CCM Fabricated by R2R

Direct Coating

Hydrogine Tech.

is developing core technologies for green hydrogen and fuel cell

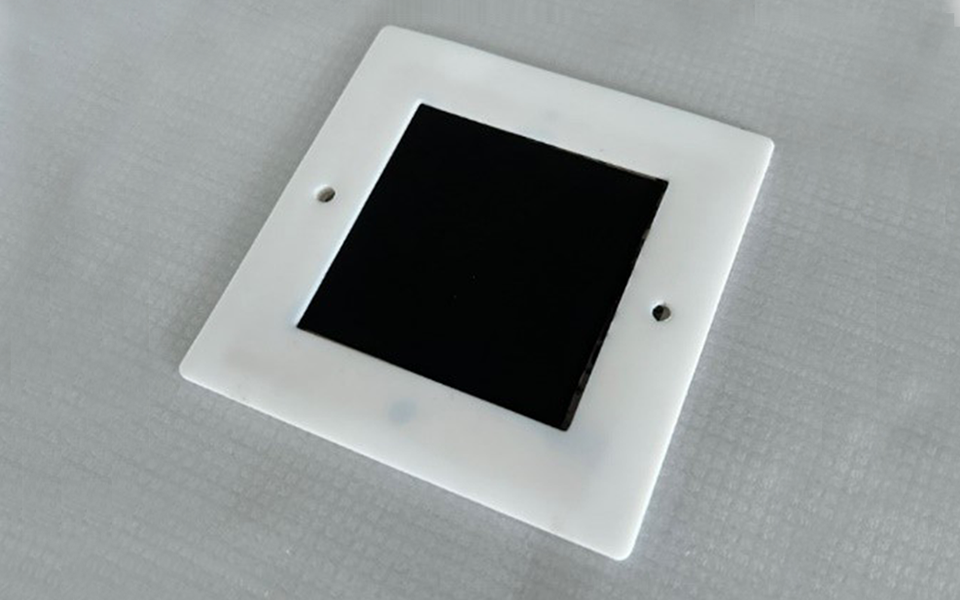

The membrane electrode assembly (MEA) is one of the key components of Solid Electrolyte Membrane Fuel Cell and Water Electrolysis system.

Generally, a MEA can be fabricated by the three different methods: (i) Catalyst coated membrane (CCM), which is coating catalyst ink onto a membrane directly, (ii) Decal transfer CCM, which is casting catalyst layer(CL) on a substrate (e.g. polytetrafluoroethylene, polyimide, etc.) and then transferring the CLs onto a membrane under high temperature and pressure, and (iii) Catalyst coated substrate (CCS), which is coating catalyst ink directly on Gas diffusion layer (GDL) (a GDL with CL is called a gas diffusion electrode (GDE)). A MEA is constructed by pressing a CCM between two GDLs, or a Polymer electrolyte membrane (PEM) between two GDEs. MEAs fabricated by CCM deliver better performance than by CCS, resulting from lower resistance due to improved ionic contact between CLs and membrane. However, CCM fabrication by direct coating on very thin membranes has been rarely demonstrated.

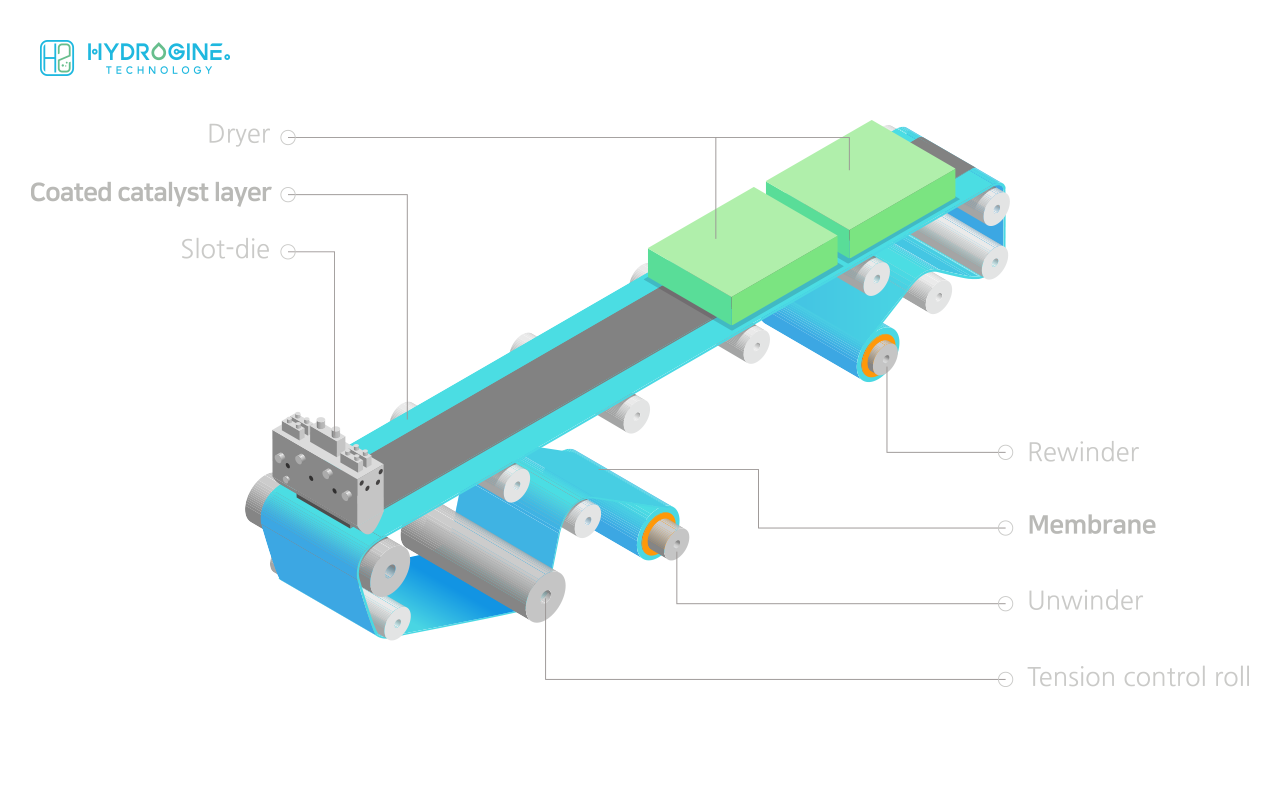

The challenge with direct coating is that the water and alcohols commonly used as the dispersion media in catalyst inks swell and deform the membrane as a large amount of ink is applied to the thin membrane in coating process. For polymer electrolyte membrane fuel cell (PEMFC) and polymer electrolyte membrane water electrolyzer (PEMWE), decal transfer process is the most common to manufacture CCM. The CLs are laminated with a membrane as solid layers, which eliminates membrane swelling. Direct coating is desirable from a manufacturing perspective because it reduces processing steps, which enables reduction of overall production costs. Roll-to-Roll (R2R) coating process like slot die and gravure coating offers significantly higher throughputs and enables to meet the requirements of industrial productivity.

Hydrogine Tech. has successfully demonstrated the direct coating of various catalyst inks on various membranes for PEMFC, PEMWE and Anion Exchange Membrane Water Electrolysis (AEMWE). Hydrogine Tech.’s ink preparation and coating techniques ensure flawless catalyst layer structure with high quality for all the applications of CCM in hydrogen and fuel cell industry.

R2R Direct Catalyst Coating Process